服装一物一码仓储管理:以数字标签重构供应链效率,激活品牌柔性生产动能

2025-05-23 13:24:00服装行业素以“快时尚”与“高库存”并存著称,品牌方既需快速响应市场趋势,又需应对库存积压、错配、损耗等供应链顽疾。传统仓储管理依赖人工盘点与纸质单据,存在信息滞后、数据孤岛、操作低效等问题,难以支撑多SKU、高频上新的业务需求。服装一物一码仓储管理系统通过为每件货品赋予唯一数字身份,实现从入库、存储到出库的全流程智能化管控,助力品牌降本增效、提升供应链韧性,在红海市场中抢占先机。

精准管控:从“模糊管理”到“颗粒度透明”的升级

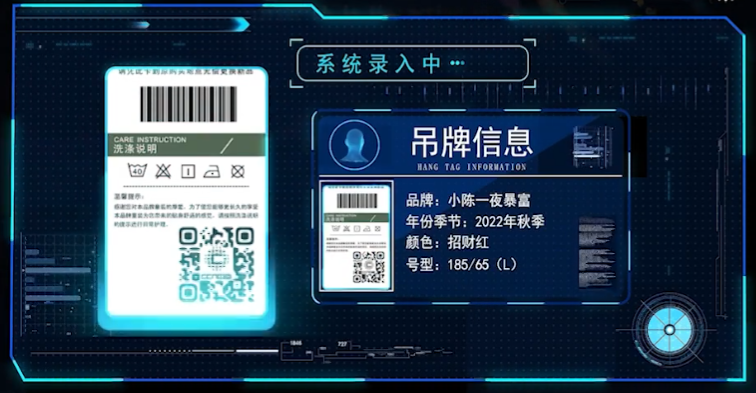

服装仓储涉及款式、颜色、尺码、批次等多维度信息,传统管理方式易因人工录入错误导致货品错发、漏发。一物一码系统通过“单品级”数字标签,将货品属性与唯一编码绑定:入库时扫码关联货品信息,系统自动分配库位;存储阶段实时监控库存数量与位置;出库时扫码核验货品匹配度,确保“单货一致”。这种“一物一码一位置”的精准管控,可将库存准确率提升至行业领先水平,减少因货品错配导致的退货与客诉,同时降低人工盘点成本。

动态调度:以数据驱动仓储资源优化配置

服装销售具有强季节性与潮流敏感性,品牌需频繁调整货品分布以匹配区域市场需求。一物一码系统通过实时数据采集与分析,为仓储调度提供决策依据:系统可追踪各仓库货品周转率、滞销品占比等指标,自动生成调拨建议;结合销售预测数据,提前将潜力货品调配至目标区域仓库,缩短订单履约周期。此外,系统支持与电商平台、线下门店数据打通,实现“线上订单-就近仓库-极速发货”的协同模式,提升消费者购物体验的同时,优化仓储空间利用率。

防伪溯源:构建品牌供应链信任壁垒

服装行业假货泛滥与窜货问题长期困扰品牌方,不仅损害消费者权益,更侵蚀品牌价值。一物一码系统通过“码链融合”技术,为每件货品建立全生命周期追溯链:从生产批次、质检报告到仓储流转记录,所有信息上链存证,确保货品来源可查、去向可追。品牌方可基于系统快速定位窜货源头,通过扫码验证真伪拦截假货流通;消费者扫码即可查看货品“数字护照”,增强对品牌正品保障的信任感。这种“技术防伪+数据溯源”的双重保障,能有效维护品牌市场秩序,提升渠道合作伙伴的合规意愿。

数字化仓储是服装品牌转型的“基础设施”

在消费需求碎片化、供应链竞争白热化的当下,服装一物一码仓储管理系统已从“效率工具”升级为“战略资产”。它不仅能帮助品牌解决库存积压、错配、损耗等现实难题,更能通过数据资产沉淀为柔性生产、精准营销提供支撑,助力品牌从“规模扩张”转向“价值深耕”。